Custom Rubber Moulding

Apart from regular rubber applications, there are so many engineering areas, where rubber is used for flexibility, cushioning, leakage protection, and many other purposes. Compared to other metal processing, rubber is very easy and cost-effective solution, so designers often design non-standard rubber components to meet their requirements.

Innovative rubber offers various solutions to make customized rubber components to OEMs and other users. These services include:

- Product design based on the application

- Mould design and engineering assistance

- Reverse engineering from existing parts

- Material selection assistance

- Develop and verify customer specifications

Innovative rubber can develop almost any design, any material rubber component, based on the application or drawing or sample.

Anti-Vibration Mounts

A rubber vibration pad/mounts is a specialized material designed to absorb shock and movement. Typically made from incompressible rubber, some of them are molded with metal, these pads/mounts deflect movement by changing shape rather than volume. They are commonly used to reduce vibrations and stabilize various appliances and machinery.

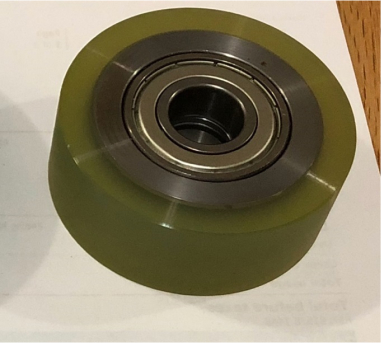

Roller

Rubber rollers may look simply, but they serve a significant purpose in several industries. These rollers are durable, cost-effective, and versatile, making them a popular choice for various applications. A rubber roller is a cylindrical material handling machine that is coated with rubber. It is a flexible and versatile tool available in various sizes and shapes.

O-RINGS

An O Ring is a doughnut-shaped article made of elastomeric rubber. It has a circular cross-section and is designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface. The O Ring seal’s purpose is to prevent an unwanted leakage or loss of gas or fluid, making it the most popular form of a seal.

We specialize in the manufacturing of rubber O-rings. we can manufacture O-rings from all types of rubber grades like silicone, Viton, EPDM, nitrile, SBR rubber etc.

Rubber Gasket

Whether you’re safeguarding sensitive machinery, preventing leaks, or ensuring flawless component integration, the humble rubber gasket plays a surprisingly critical role. Their primary purpose is to establish a secure and leak-proof seal between two surfaces, whether sealing flanges, pipes, or valves. At Asian Sealing Products, we understand that your industrial applications demand the best in rubber gasket technology. We are a trusted rubber gasket manufacturer and supplier, providing reliable and effective products that ensure optimal performance and sealing efficiency.

Rubber gaskets have a broad range of applications across various industries, including Oil and Gas, Pharmaceuticals, Food and Beverage, Electronics and Semiconductor, Construction, Aerospace, Chemical and Petrochemical

Rubber Seal

They play a crucial role in many applications. They are designed to prevent leaks, resist chemicals and high pressures, and reduce noise and vibration. In other words, they keep things where they're supposed to be.

Rubber seals come in many different shapes, sizes, and materials, each with its own advantages and limitations. Some of the most common types include O-rings, gaskets, seal strips and diaphragms. They can be made of natural or synthetic rubber, silicone, Viton, EPDM, Nitrile, and other materials. Choosing the right rubber seal for your needs involves considering factors such as temperature range, chemical compatibility, durometer or hardness, and cross-section shape.

Rubber seals are a vital component in multiple applications and industries. In the automotive industry, they are used to prevent leakage of fluids and gases. Rubber seals are also a popular choice in the marine industry due to their resistance to saltwater corrosion. Medical equipment and electronics also rely on high-quality rubber seals for the prevention of fluid and air leaks.

Re-Lagging of Rubber Rollers

Rubber rollers are subjected to various types of wear and tear due to continuous use. Some common problems which can arise with rubber rollers are roller slipping, roller wear and tear, damage to roller surface, and improper alignment.

Roller slipping can occur when there is an insufficient amount of friction between the roller and the surface it is moving on. Roller wear and tear is when the surface of the roller starts to break down due to continuous use. Damage to roller surface can occur due to excessive pressure and improper handling of the roller. Improper alignment can also cause problems like uneven wear and tear of the roller surface.

We offer re lagging services of most of the rollers made from Nitril, neoprene, EPDM, natural etc. We also offer brand new rollers with metal shaft as per your drawing or sample.

+1 647-719-8731

+1 647-719-8731 innovativerubbers@gmail.com

innovativerubbers@gmail.com